Polyurethane foam is one of the key rigid foam insulation materials used in roofing and wall systems. It is an organic polymer with characteristics between rubber and plastic. Its outstanding properties include excellent thermal insulation, sound absorption, environmental durability, oil resistance, and flexibility.

Polyurethane foam can expand 20–100 times from its original volume, forming a cellular structure consisting of both closed-cell and open-cell forms. Closed-cell foam allows significantly less vapor transmission compared to open-cell foam. Polyurethane foam also provides strong heat resistance, with a decomposition temperature ranging between 230–250°C

More Economical:

Save on electricity usage for air conditioning thanks to its low thermal conductivity. It significantly reduces heat transferred through the roof—up to 496.174 (Btu/ft²·°F·hr) for a 16-square-meter room.

More Comfortable Cooling:

High thermal resistance coefficient (R-value)

Low thermal conductivity coefficient (K-value)

Reduces roof surface heat by up to 10°C

Stronger:

High-density PU foam offers superior strength compared to standard PU foam. It can withstand compressive loads of up to 1 ton per square meter, while still being 20 times lighter than water.

Safer:

The PU foam is formulated with fire-retardant additives, reducing the risk of fire (DIN 4102 Class B3).

It is also environmentally friendly, produced through a safe manufacturing process using leading technology in Southeast Asia.

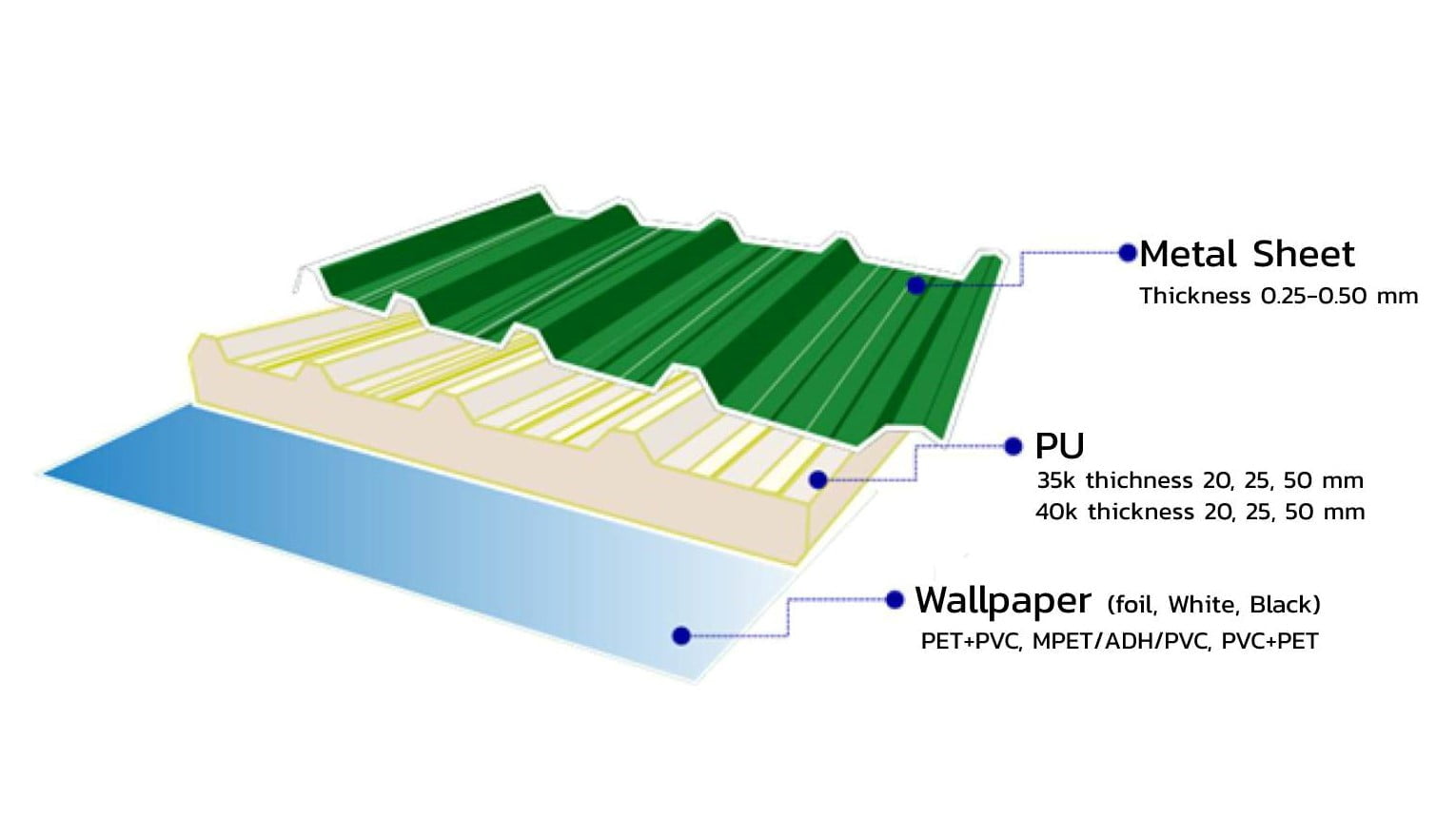

Metal sheet : Thickness 0.25-0.50 mm

PU : Thickness 20,25,50 mm

Wallpaper (Foil, White, Black)

PET+PVC, MPET/ADH/PVC, PVC+PET

Metal sheet : Thickness 0.25-0.50 mm

PU : 35K thickness 20,25,50 mm

Metal sheet : Thickness 0.30-0.50 mm

| PU FOAM "30K OD" STANDARD | Comparison | Other Products |

|---|---|---|

| Does not deform; withstands compression up to 60 KPa | Compressive Strength (ASTM D1621-16) | Deforms easily; withstands less than 40 KPa |

| Strict thickness control using certified testing rooms and measuring devices | Core Density (ASTM D1622-14) | No thickness control standards; no measuring equipment |

| Contains fire-retardant additives; burns but does not drip flaming droplets | Fire Test (UL94) | Incorrect amount of fire-retardant chemicals; fails UL94 “no flaming droplet” standard |

| Water-based formula with no Blowing Agent chemicals; safe for users and the environment | Main Components (ASTM D6226) | Uses chemical Blowing Agents, increasing long-term health and environmental risks |

| Product warranty: no deformation of foam core, guaranteed up to 5 years | Warranty Test (ASTM D2126) | No product warranty provided after installation |