One of the key rigid foam insulation materials used in roofing and wall systems is an organic polymer that possesses characteristics between rubber and plastic. It offers outstanding properties such as excellent thermal insulation, sound absorption, environmental durability, oil resistance, and flexibility.

Polyurethane foam can expand 20–100 times its original volume, forming a cellular structure consisting of both closed-cell and open-cell types. Closed-cell foam allows significantly less vapor transmission compared to open-cell foam. In addition, polyurethane foam provides excellent heat resistance, with a decomposition temperature ranging from 230–250°C, making it highly suitable for insulation applications.

| Product Property | PU ULTRA | Test Method |

|---|---|---|

| Cell Structure | Open Cell > 70% | ASTM D6226 |

| Overall Density | 25 ± 3 Kg/m³ | ASTM D1622-14 |

| Core Density | 20 ± 3 Kg/m³ | ASTM D1622-14 |

| Dimensional Stability (% Size Change) | < 3% | ASTM D2126 |

| Tensile Strength | 30 - 40 KPa | ASTM D1621-16 |

| Fire Resistance Properties | Class B3 | DIN 4102 |

| Thermal Conductivity (K-Value) @24°C Mean | 0.0290 – 0.0320 W/m·K | ASTM D2126 |

| Product Specifications (Thickness in mm) | 20 | 25 | 50 | Test Method |

|---|---|---|---|---|

| Thermal Conductivity (K-Value) (W/m·K) @24°C mean |

0.03 | 0.03 | 0.03 | ASTM C518 |

| K-Value Btu·in/hr.ft².F @75°F mean |

0.208 | 0.208 | 0.208 | |

| Thermal Resistance (R-Value) K·m²/W @24°C mean |

0.6667 | 0.8333 | 1.6667 | ASTHRAE GR P158 |

| R-Value hr.ft².F/Btu @75°F mean |

0.0962 | 0.1202 | 0.2404 | |

| Residual Heat (Btu/ft²·°F·hr) | 362.86 | 444.36 | 806.76 | |

| Roof Surface Heat Reduction (°C) | ≈ 5.5°C | ≈ 6.6°C | ≈ 11.0°C | |

| Energy Savings (THB/Month)) | 42.829 | 52.43 | 95.2 |

* Based on calculations using a room size of 16 square meters, air conditioner set at 25°C, operating 8 hours per day, with an outdoor temperature of 40°C — comparing metal sheet roofing with insulation versus without insulation.

** Test results referenced from controlled laboratory conditions under the Product Research & Development Division, with room temperature maintained at 25°C and a heat source of 200 watts.

*** Calculation based on a 1-ton air conditioner (12,000 BTU) consuming 1.25 kW/hr, with an electricity cost of 2.6 THB per kW, operating 8 hours per day.

More Energy Efficient:

Reduce electricity usage from air conditioning with a low thermal conductivity insulation material. It effectively decreases heat transfer through the roof by up to 496.174 (Btu/ft²·°F·hr) for a 16-square-meter room, resulting in significant energy savings and improved indoor comfort.

Cooler and More Comfortable:

Features a high thermal resistance (R-value) and a low thermal conductivity (K-value), helping to reduce roof surface heat by up to 10°C, resulting in a noticeably cooler indoor environment.

Stronger and More Durable:

Made with high-density PU foam, which is stronger than standard polyurethane foam, it can withstand compressive loads of up to 1 ton per square meter while remaining extremely lightweight—approximately 20 times lighter than water.

Safer and More Reliable:

Formulated with fire-retardant additives, the high-quality PU foam helps reduce the risk of fire spread (DIN 4102 Class B3) while maintaining excellent insulation performance. It is also environmentally friendly, produced using safe and advanced manufacturing technology—recognized as one of the leading processes in Southeast Asia.

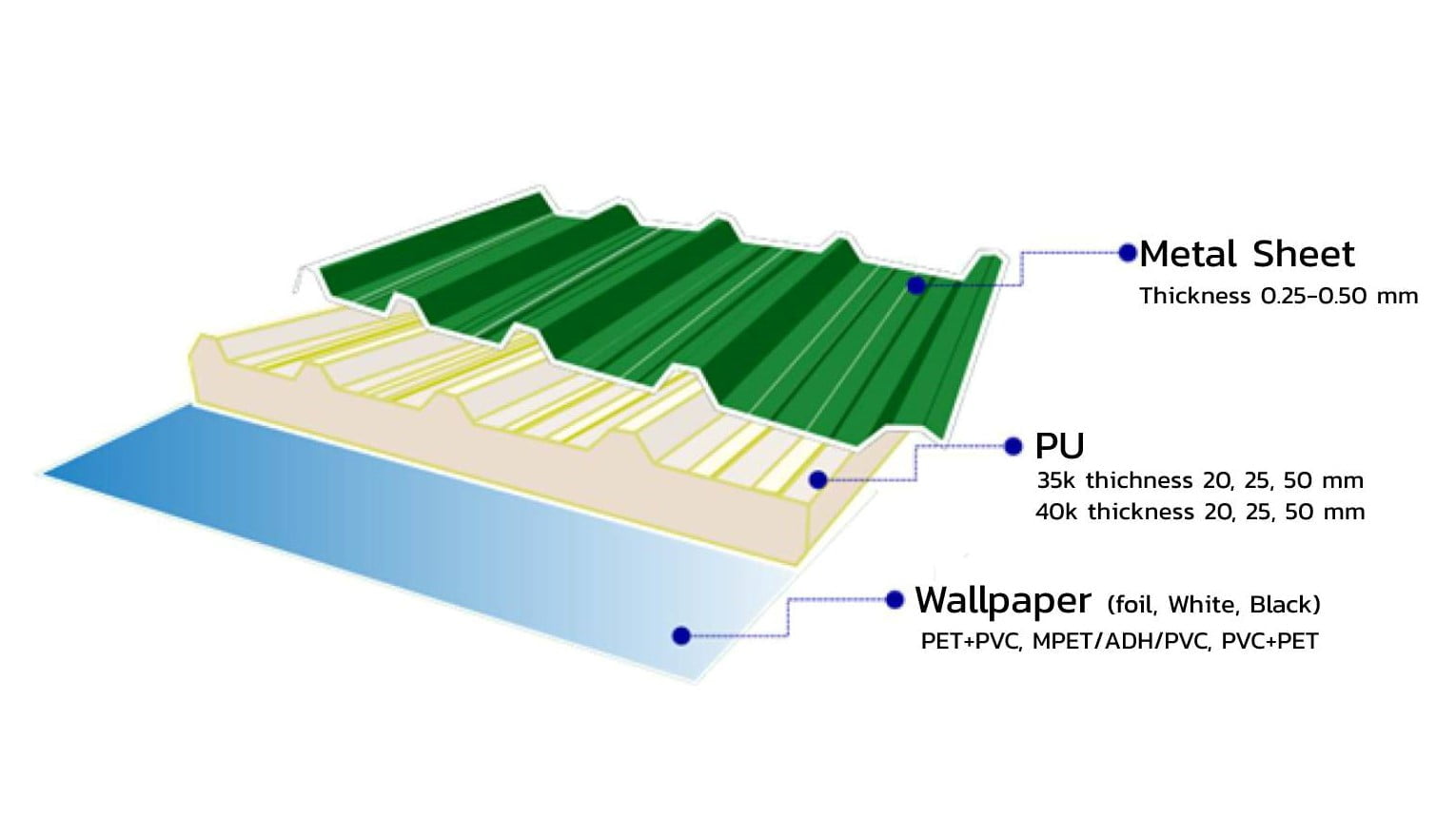

Metal sheet : Thickness 0.25-0.50 mm

PU : Thickness 20,25,50 mm

Wallpaper (Foil, White, Black)

PET+PVC, MPET/ADH/PVC, PVC+PET

Metal sheet : Thickness 0.25-0.50 mm

PU : 35K thickness 20,25,50 mm

Metal sheet : Thickness 0.30-0.50 mm

| Product Property | Test Method | BK PU ULTRA | OTHERS | Performance Comparison |

|---|---|---|---|---|

| Thermal Conductivity: K-Value | ASTM D2126 |

0.0290 – 0.0320 (W/m.K) @24°C mean |

0.0340 – 0.0370 (W/m.K) @24°C mean |

16% |

| Fire Resistance Properties | Class DIN 4102 |

↓

↓

|

↓

↓

|

65% |

| Material | Density (kg/m³) | Thermal Conductivity (W/m·K) | Advantages | Disadvantages |

|---|---|---|---|---|

| Fiberglass | 16–48 | 0.035–0.050 | Lightweight and inexpensive | Moisture absorbent |

| Fiberglass Board | 60–180 | 0.035–0.045 | Lightweight and inexpensive | Moisture absorbent |

| Rockwool Board | 100–150 | 0.035–0.045 | Low cost | Heavy and not durable |

| BK PU ULTRA | 17–23 | 0.029–0.032 | Excellent thermal insulation and strong | Combustible, but contains fire-retardant additives |

| Cellulose Fiber | 25–55 | 0.030–0.040 | Not commonly used | Easily produced / low-grade material |